The workflow for creating, fabricating, and hanging conduit runs using Autodesk MEP, Revit, Fabrication, and Trimble Smart Tools is a multi-step process that bridges the gap between design intent and on-site installation. Here is a breakdown of the procedure and the significant benefits of using this integrated toolset.

The Procedure: From Design to Installation

Step 1: Design and Modeling in Autodesk Revit MEP

The process begins in Autodesk Revit MEP, where the electrical designer models the conduit runs.

- Design Intent: The designer lays out the conduit system based on the electrical design drawings, schematics, and project requirements. This includes specifying the size, type, and general path of the conduit.

- Routing and Sizing: Revit’s built-in tools allow for automatic routing of conduit, and the designer can specify the trade size and type (e.g., EMT, Rigid, IMC).

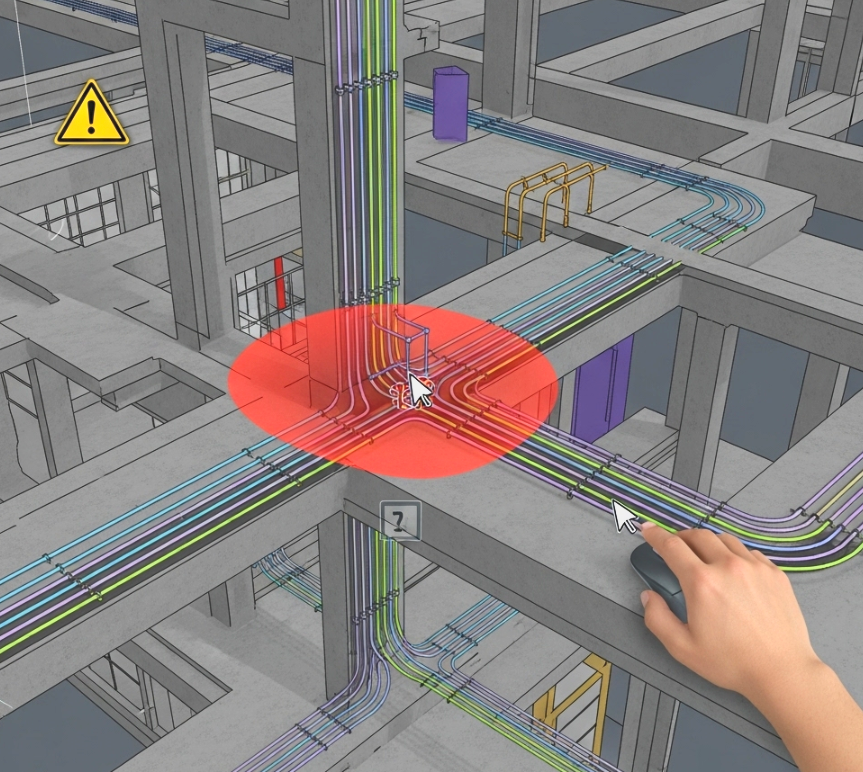

- System Integration: The conduit is connected to electrical fixtures, panels, and equipment, ensuring the entire electrical system is modeled accurately within the project. The model is also coordinated with other disciplines (structural, mechanical, architectural) to avoid clashes.

Step 2: Detailing and Fabrication in Autodesk Fabrication & Trimble SysQue

Once the design is complete, the model transitions from a conceptual design to a detailed fabrication model.

- Conversion to Fabrication Parts: The design-level conduit in Revit is converted into fabrication-level content. This can be done by linking the Revit model to an Autodesk Fabrication database or, more effectively, by using a tool like Trimble SysQue.

- Trimble SysQue for Fabrication Detailing: Using SysQue, the designer or detailer replaces the generic Revit conduit with real-world, manufacturer-specific fabrication parts. This content includes detailed information such as product numbers, lengths, cut lists, and fitting connections. SysQue’s database is synchronized with the fabricator’s real-world inventory.

- Automatic Spooling and Labeling: The conduit runs are automatically “spooled” into manageable sections for prefabrication. SysQue can also generate spools sheets and labels, detailing the components, lengths, and assembly instructions for each spool.

- Hanger Placement: The designer uses Trimble SysQue’s automated tools to place hangers and supports along the conduit runs based on a set of rules (e.g., spacing requirements from code). This ensures the conduit system is properly supported and ready for installation.

Step 3: Layout and Installation with Trimble Smart Tools

The detailed and fabricated conduit information is now ready to be used on the job site.

- Export to Layout Tools: The hanger locations and conduit path data are exported from Revit and SysQue to Trimble layout tools. This is often done by generating a point file that contains the precise coordinates for each hanger and support location.

- On-Site Layout: Field crews use Trimble Smart Tools (e.g., robotic total stations, handheld controllers) to electronically “lay out” the hanger locations on the deck or wall. The robotic total station reads the point file and guides the crew to the exact location where each hanger needs to be installed, eliminating the need for manual measurements and string lines.

- Installation: With the hangers precisely installed, the pre-fabricated conduit spools are brought to the site and easily snapped into place. The fabrication drawings and spool labels make the assembly process straightforward and efficient.

The Benefits of Using These Tools

The integrated use of these tools provides a significant competitive advantage and streamlines the entire construction process.

- Increased Accuracy and Reduced Rework:

- Revit MEP: Provides a coordinated 3D environment, allowing for clash detection with other trades before construction begins. This eliminates costly on-site conflicts and rework.

- Trimble SysQue: By using real-world fabrication parts, the model is a digital twin of what will be built. The automated hanger placement and spooling features ensure everything fits perfectly, reducing cutting and waste on-site.

- Trimble Smart Tools: The electronic layout of hangers is far more accurate than manual methods. This precision ensures that the prefabricated conduit spools fit perfectly on the first attempt, saving time and labor.

- Enhanced Productivity and Efficiency:

- Automation: Tools like SysQue automate tedious and error-prone tasks like spooling and generating bills of materials (BOMs) and cut lists.

- Prefabrication: By pre-fabricating conduit spools off-site in a controlled shop environment, the on-site installation becomes a simple assembly process. This reduces labor costs and allows for faster project completion.

- Streamlined Workflow: The digital data flows seamlessly from the design model in Revit to the fabrication shop in SysQue and finally to the field layout with Trimble Smart Tools. This eliminates the need for manual data entry and reduces the potential for human error.

- Improved Collaboration and Communication:

- Single Source of Truth: The Revit model serves as a centralized hub for all project information. Everyone, from the designer to the fabricator to the installer, is working from the same accurate model.

- Visual Communication: The 3D models and fabrication drawings are easy to understand for all stakeholders, improving communication and reducing misinterpretations.

- Cost Savings:

- Reduced Material Waste: Precise cut lists and pre-fabrication minimize material scrap.

- Lower Labor Costs: The automation of detailing and the efficiency of pre-fabrication and electronic layout significantly reduce the time spent on installation.

- Fewer Delays: Proactive clash detection and accurate fabrication prevent costly on-site delays and scheduling conflicts.

In summary, this integrated workflow transforms the traditional, often disjointed, process of conduit installation into a highly efficient, accurate, and predictable one. It empowers designers to create smarter models that are directly usable for fabrication and installation, ultimately leading to higher-quality projects delivered faster and more affordably. Contact us for additional information.

Leave A Comment